Vibration damping is crucial for mechanical systems' stability, performance, and lifespan, with plastic intake tubes gaining popularity in automotive modifications for their lightweight design and flexibility. However, these tubes face durability issues in harsh environments, are susceptible to heat degradation, and may require more frequent replacement due to warping or cracking. This comparison explores the pros and cons of plastic intake tubes versus traditional metal alternatives, emphasizing material choices for optimal vibration control while balancing cost, weight, corrosion resistance, and signal precision in various applications.

Vibration damping is a critical aspect of mechanical engineering, ensuring smooth operations and extending equipment lifespan. This article delves into the fundamental principles of vibration control, exploring an innovative solution: the plastic intake tube. We compare traditional methods with this modern alternative, highlighting its pros and cons. By understanding these aspects, engineers can make informed decisions, leveraging the benefits of plastic intake tubes for effective vibration management in various applications.

- Understanding Vibration Damping: The Basics

- Plastic Intake Tube: Pros and Cons

- Comparison: Traditional Methods vs. Plastic Intake Tubes for Vibration Control

Understanding Vibration Damping: The Basics

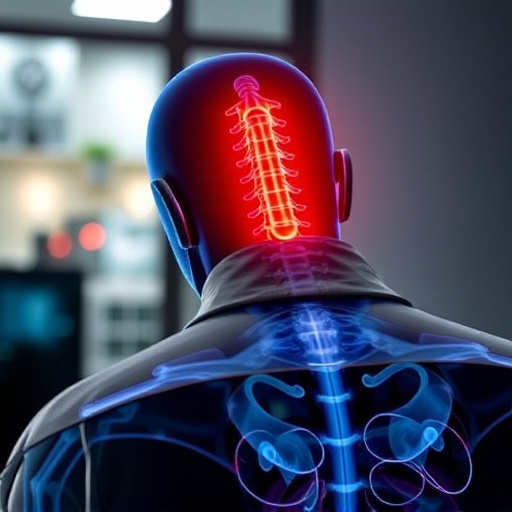

Vibration damping is a critical process that helps control and reduce unwanted vibrations in mechanical systems. At its core, it involves converting kinetic energy from vibrating components into heat, which can then be dissipated. This not only enhances the overall stability and performance of machines but also extends their lifespan by preventing structural damage caused by excessive vibrations.

When considering solutions for vibration damping, one common component is the plastic intake tube. These tubes offer several advantages, including lightweight construction that reduces overall system weight and improved resonance control compared to metal alternatives. However, they are not without drawbacks; plastics may have limited durability in harsh environments and can be susceptible to degradation from heat or chemicals. A thorough comparison of pros and cons is essential before selecting a damping material, as it directly impacts the effectiveness and longevity of vibration control mechanisms.

Plastic Intake Tube: Pros and Cons

Plastic intake tubes have become a popular choice in many automotive modifications, offering both advantages and disadvantages when it comes to vibration damping. In terms of pros, plastic intake tubes are lightweight, making them an attractive option for performance enthusiasts aiming to reduce overall vehicle weight. This material is also flexible, allowing for easier routing around tight spaces and engine components, which can be a benefit during installation. Additionally, plastic intakes often come with advanced designs, incorporating features like pulse chambers and divergent tubes to enhance engine sound and potential power gains.

On the downside, plastic intake tubes are susceptible to warping or cracking over time due to extreme temperatures and engine heat. This vulnerability can lead to air leaks, compromising engine performance and fuel efficiency. Moreover, while some plastic intakes claim noise reduction, they might not effectively dampen high-frequency vibrations, potentially resulting in a less refined driving experience. In comparison with metal alternatives, plastic intake tubes may require more frequent replacement and maintenance, which could be a consideration for cost-conscious consumers.

Comparison: Traditional Methods vs. Plastic Intake Tubes for Vibration Control

In the pursuit of achieving optimal vibration control, a critical consideration is the choice between traditional methods and modern innovations like plastic intake tubes. Traditional techniques, which often involve heavy metal components, have long been the industry standard but come with inherent drawbacks. These include added weight, increased material costs, and potential corrosion issues over time.

On the other hand, plastic intake tubes offer a compelling alternative with several advantages. They are lightweight, significantly reducing overall vehicle weight, which can lead to improved fuel efficiency. Plastic materials are also cost-effective and resistant to rust, making them low-maintenance options. However, they may not be as effective in extreme conditions or for high-performance applications due to their inherent flexibility, which can sometimes result in a less precise transmission of control signals compared to stiffer metal components.

In conclusion, understanding vibration damping is key to enhancing machinery performance and reducing noise pollution. While traditional methods have their merits, the plastic intake tube stands out for its lightweight, cost-effective, and efficient vibration control capabilities. Our comparison highlights the significant advantages of plastic intake tubes, making them a viable and preferable choice in various industrial applications. By embracing these innovative solutions, manufacturers can experience improved operational efficiency and quieter environments.